Application of In-Furnace Laser Detectors for Billet Positioning in Reheating Furnaces

Yo. Descripción general del producto

The In-Furnace Laser Detector (Enlace) is a high-power laser detector designed for harsh industrial environments in metallurgy. Equipped with an infrared semiconductor laser emitter, it delivers exceptional penetration and ultra-long working distances, ensuring stable performance in extreme conditions (high temperatures, humidity, mist, polvo, etc.).

II. Principio de funcionamiento

The detector operates on the principles of laser linear propagation and reflection:

Emisión láser: The infrared laser beam is emitted toward the furnace interior.

Reflection: The beam reflects off the billet surface.

Recepción de señal: The reflected signal is captured by the receiver and converted into an electrical signal.

Position Calculation: Billet position and distance are determined using signal intensity and time delay analysis.

III. Escenarios de aplicación

In reheating furnaces, the detector is primarily used for:

Billet Position Monitoring:

Tracks real-time billet positions to ensure proper alignment during heating, improving thermal uniformity and efficiency.

Automated Control Integration:

Interfaces with furnace automation systems to enable auto-positioning and tracking. Adjusts heating parameters or triggers control actions based on billet movement.

Protección de seguridad:

Monitors billet trajectories and positions to detect anomalies, triggering alarms or emergency shutdowns to safeguard personnel and equipment.

IV. Ventajas clave

The detector excels in billet positioning applications due to:

Alta precisión & Stability:

Advanced laser technology and signal-processing algorithms ensure submillimeter accuracy.

Strong Penetration Capability:

Infrared laser emitter penetrates high-temperature zones and dense particulate environments.

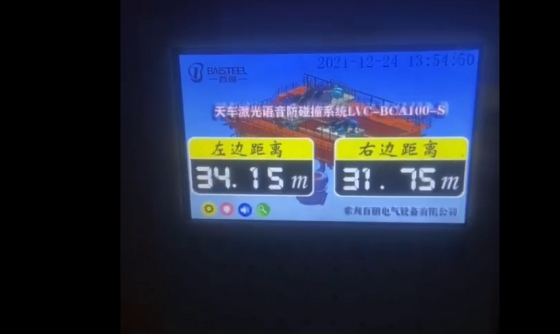

Ultra-Long Working Distance:

Supports billet positioning in large-scale furnaces (up to 100+ meters).

Ease of Integration & Mantenimiento:

Standardized interfaces (p ej., Modbus, Ethernet/IP) simplify integration with control systems. Low-maintenance design reduces operational costs.

V. Conclusión

The In-Furnace Laser Detector enhances reheating furnace operations through precision positioning, rugged reliability, and automation compatibility. By optimizing heating efficiency, seguridad, and maintenance workflows, it drives sustainable advancements in metallurgical production.

Aceros Baisteels

Aceros Baisteels