Application of Through-Beam Laser Detectors in Steel Rolling Production Lines

I. Product Overview

The Through-Beam Laser Detector (Link) is a 650 nm red laser-based device designed for detecting opaque objects in metallurgical production lines. With long-range detection, robust anti-interference, and easy installation, it operates reliably in harsh environments (humidity, mist, dust) for extended periods.

II. Working Principle

The detector comprises a transmitter and receiver:

Laser Emission: The transmitter projects a red laser beam.

Signal Interruption: When an object blocks the beam, the receiver detects the change in reflected light.

Output Trigger: A digital output signal is activated upon interruption.

Signal Optimization: Built-in digital energy display helps fine-tune alignment for optimal signal quality.

III. Applications in Steel Rolling Lines

Key use cases include:

Object Detection & Positioning:

Tracks steel products or billets on the line to ensure synchronized rolling and accurate counting.

Safety Protection:

Monitors critical zones (e.g., mill entry/exit) for blockages or misalignments, triggering emergency shutdowns to protect personnel and machinery.

Automated Control:

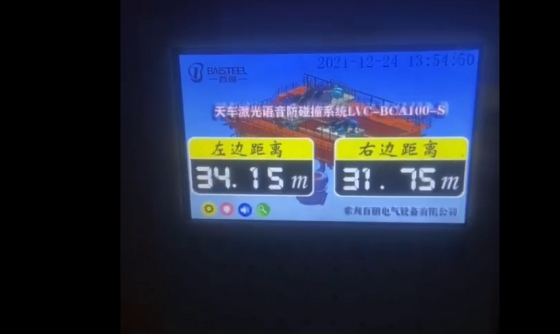

Integrates with PLC/SCADA systems to enable real-time data exchange for intelligent, automated production.

Fault Diagnosis & Alerts:

Energy/fault alarm outputs enable proactive maintenance, reducing unplanned downtime.

IV. Key Advantages

The detector excels in steel rolling applications due to:

High-Precision Detection:

Laser technology achieves sub-millimeter resolution for precise object sizing/positioning.

Anti-Interference Performance:

Resists environmental noise (dust, moisture, vibrations) for stable operation.

Quick Installation & Calibration:

Modular design and intuitive setup minimize deployment time and labor costs.

Durability:

Industrial-grade materials and IP67-rated housing ensure long-term reliability with minimal maintenance.

V. Conclusion

The Through-Beam Laser Detector enhances steel rolling efficiency and safety through precision, automation, and rugged design. By streamlining operations and reducing risks, it supports cost-effective, intelligent automation in heavy industry.

베일스틸

베일스틸