The Hot Metal Detector (증권 시세 표시기) is designed to track and detect high-temperature workpieces at different stages of operation on a hot rolling line. It is important to rely on accurate and reliable sensors that are insensitive to the size, position, and temperature of the rod and can detect the head or tail of the rod in less than 1 ms at important operating positions such as cutting control (workpiece head and tail cutting or fixed length cutting). For these applications, it is recommended to use scanning thermal metal detectors because their lateral field of view is very narrow. The new generation technology using infrared detectors can detect workpieces with temperatures as low as 180 ℃, which is used for detecting workpieces after water quenching.

Typical applications

Temperature measurement of rolled pieces

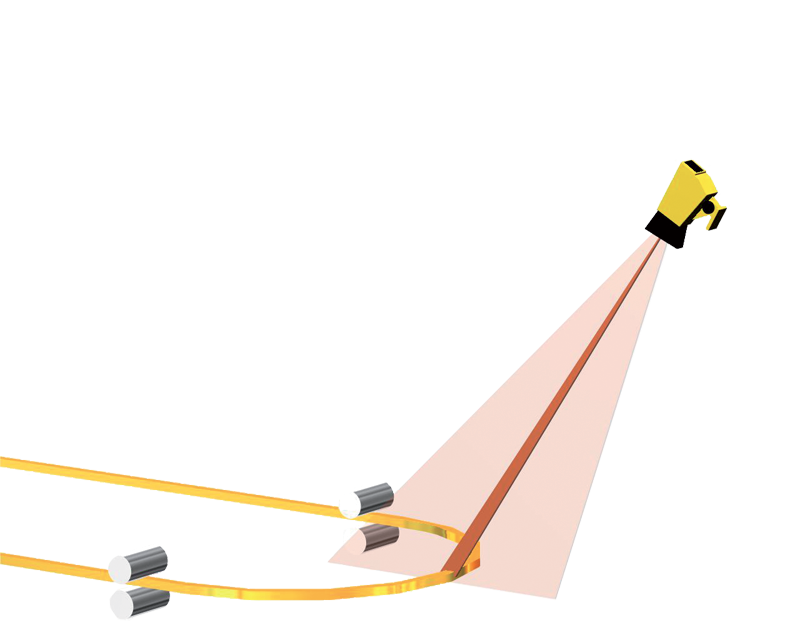

Loop detection

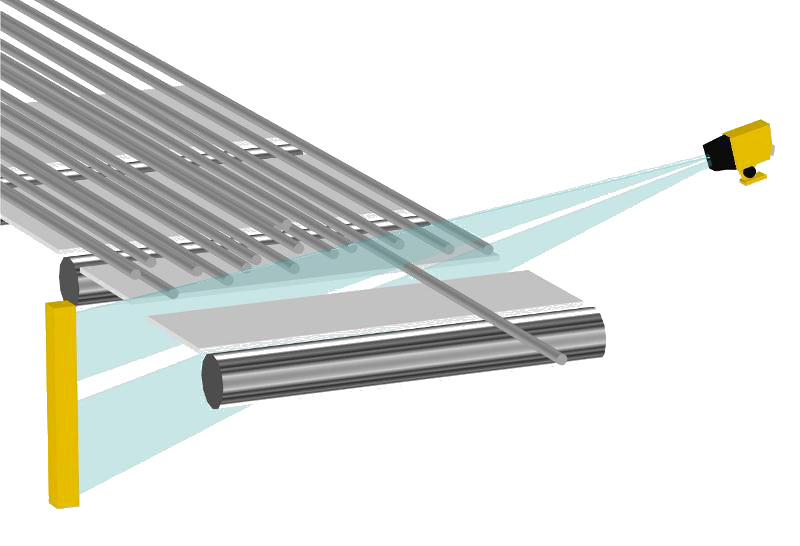

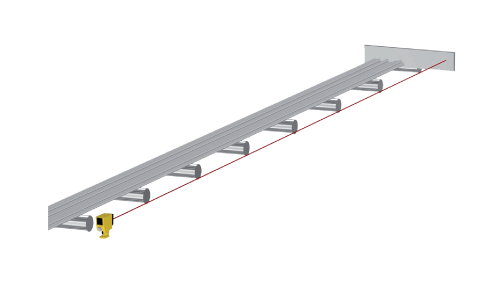

Rolling position detection

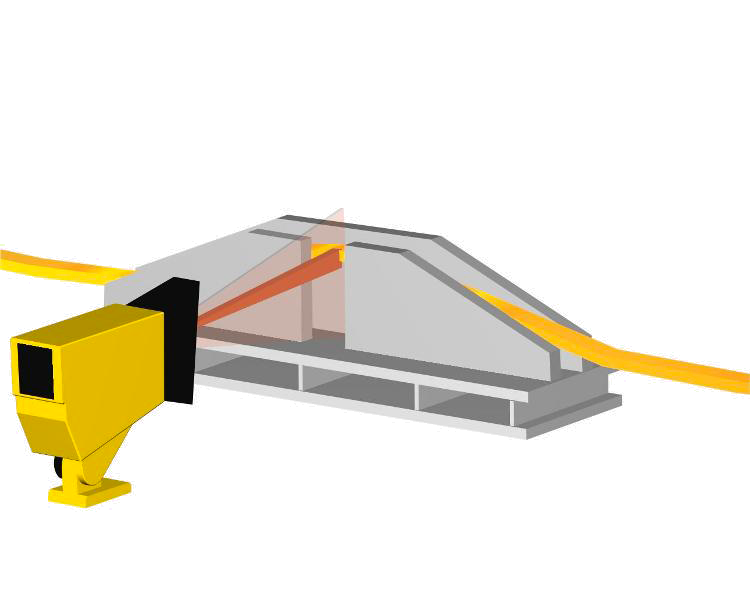

Flying shear control

Detection of cold zone position of bar material

Bar Counting

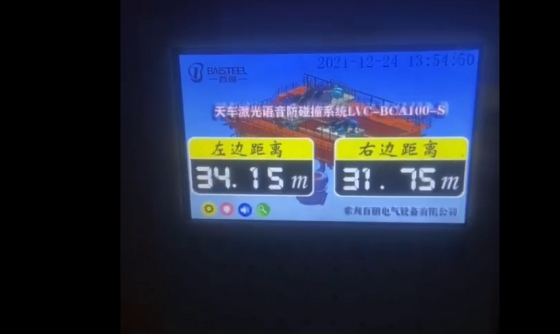

베일스틸

베일스틸