The dual color infrared thermometer can be widely used in the metallurgical industry (wire rods, hot-rolled plates, forging) and casting industry, cement kilns, induction heating, single crystal silicon and polycrystalline silicon, and other industrial applications for temperature measurement. Especially suitable for long-distance measurement of small targets, materials with easily variable emissivity, and precise temperature measurement in situations with strong attenuation.

It can meet the measurement of various ultra-high temperature objects and has a wide dynamic range.

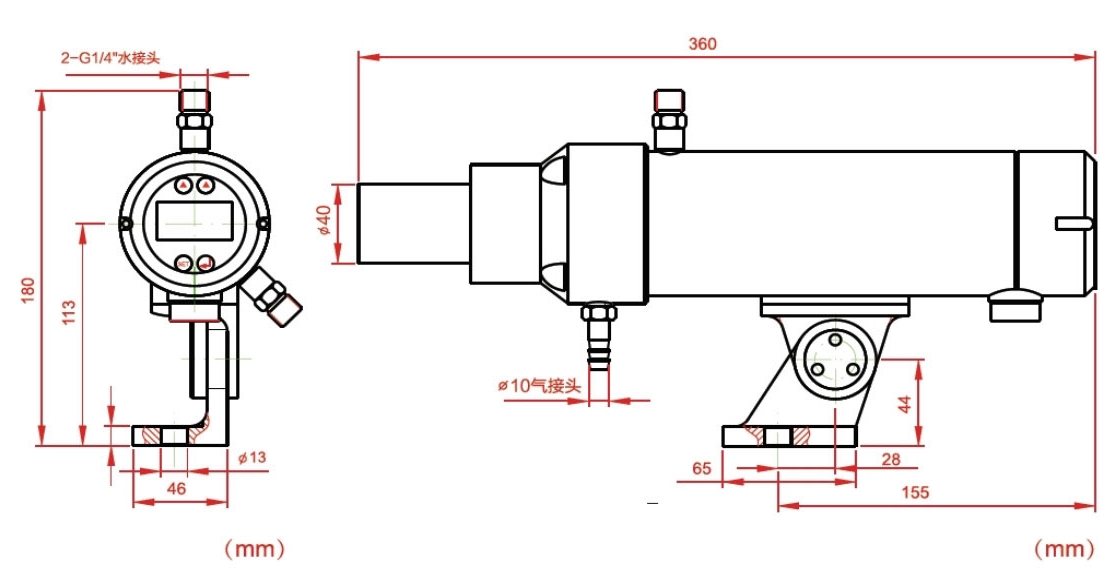

The dual color thermometer has a sturdy appearance and uses a stainless steel movement (with a diameter of only 59mm). It comes standard with a stainless steel protective cover (with blowing and cooling functions), and the sealing components are made of high-temperature resistant rubber with a protection level of IP65, suitable for industrial applications.

Detecting targets in environments such as water vapor, dust, changes in target size, partial occlusion, and changes in emissivity, even if the detection signal attenuates by 95%, will not have any impact on the temperature measurement results. Software and hardware design, suitable for processing signals up to hundreds of thousands of times, can meet users’ requirements for instrument accuracy, repeatability, and other aspects.

Product Features

The temperature measurement range covers 350 ℃ to 3000 ℃

The temperature measurement accuracy can reach 0.5%, with a repeatability of 2 ℃ and a resolution of 0.1 ℃

Response time adjustable from 5ms to 99.99 seconds

Using an adjustable focus lens, measuring distances from 0.35m to infinity

High brightness green LED light source or visual eyepiece, clearly displaying the position and size of the measured target

PID constant temperature control is adopted for the detector to eliminate the influence of environmental temperature on measurement

Combining dual color and monochrome temperature measurement functions

In dual color mode, there is a lens dirt detection function

It has antioxidant measurement function and is not affected by oxides during measurement

Adopting industrial grade OLED screen as the display interface, the human-machine interface is friendly

Rich peripheral interfaces: 2 independent analog outputs, 2 alarm outputs, 1 level output, and 1 RS485 communication interface.

Up to 26 thermometers can be cascaded on the bus, and networked control can be achieved through a PC

Design software and hardware watchdogs, hardware EMI filtering, etc. to improve system stability

Can resist 2500VDC pulse group interference

Baisteels

Baisteels