Application and Features:

This detector is widely used, mainly for tracking any shape of metal (plate, billet, wire, bar, etc.) in continuous casting and hot rolling.

This detector is a scanning type hot metal detector, which can detect even very small parts of hot metal within the detector’s field of view. Therefore, the detector can be installed very far away from the object being measured. This detector can detect objects with a minimum temperature of 200 °C.

This detector uses an OLED display screen, and various parameters of the detector are fully displayed on the screen, allowing users to easily understand the operating status at a glance.Principle:

Scanning principle

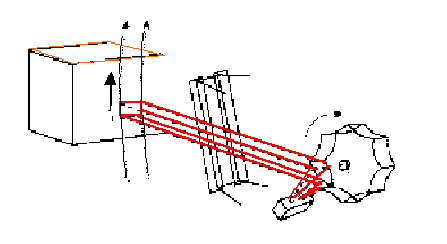

The optical area of this detector is scanned by a rotating drum with a polygon mirror. If a hot metal passes through the field of view of the detector, the detected infrared light is reflected onto the photovoltaic cell, as shown in the following figure:

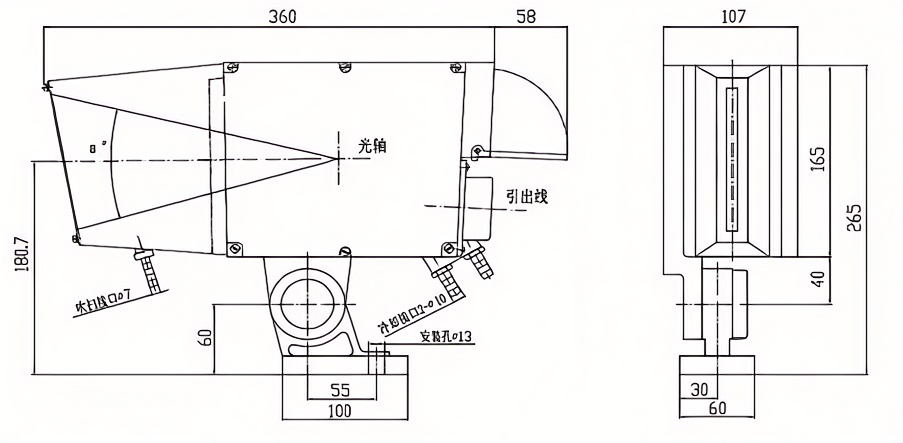

Three vertical field of view angles are available: 10 °, 30 °, and 50 °.

The horizontal viewing angle (up to 3 graus académicos) can be adjusted through the light shielding plate on the protective cover of the detector.

Whether the entire or partial hot metal is within the scanning domain, the detector can operate.

Photodetector

This detector uses an indium gallium arsenide photodetector. Its spectral response range can detect metal thermal radiation as low as 200 °C, and combined with the principle of multi-faceted mirror scanning, it has the following characteristics:

1. After the hot metal leaves the scanning area, it can quickly recover and reduce the dwell time of the output signal.

2. The signal-to-noise ratio has been improved. Even under infrared reflection background or roller conveyor thermal radiation background, low-temperature targets can still be detected.

3. The use of pulse signal amplification can effectively reduce the temperature drift of the sensor.

Automatic control of action threshold hysteresis

The action threshold of this detector has a hysteresis adjustment function, and the initial action threshold can be adjusted through the potentiometer on the control panel. When the detected thermal metal radiation energy signal intensity is greater than the action threshold, the action threshold will automatically decrease. After the thermal metal leaves, the action threshold will return to its initial value. This hysteresis characteristic enhances the stability of the detector’s operation, preventing the sensor from being affected by black spots, water vapor, iron oxide scale, and uneven target temperature.

Installation and debugging:

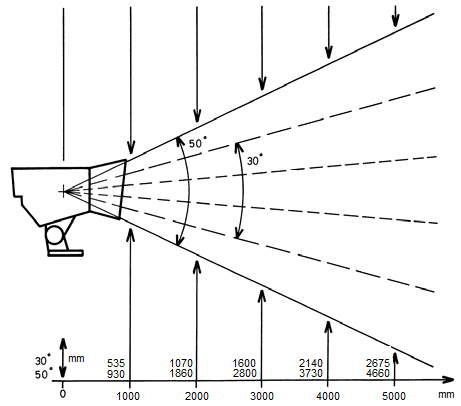

Installation distance

The distance between the vertical detection area of this detector and the target is a functional relationship corresponding to the scanning angle (10 ° 30 ° 50 °), as shown in the following figure:

The principle for selecting installation distance is:

For targets with extremely high temperatures, the installation distance should be chosen as far as possible to avoid damage to the product caused by thermal radiation.

For targets with low temperature or low infrared radiation factor, the installation distance should be chosen as close as possible to ensure sufficient signal-to-noise ratio.

Note: The target to be detected does not necessarily have to completely fill the scanning field of view of the detector. As long as any part is within the scanning field of view, this detector can reliably detect it.

The recommended installation distance between the detector and various targets is shown in the following table:

Baisteels

Baisteels