Applications of Laser Rangefinders in Steelmaking Production Lines

Eu. High-Precision Dimensional Measurement & Control

Billet/Ingot Dimension Inspection

Measures length, width, and thickness of continuously cast billets/blooms to ensure cutting accuracy meets process standards.

Monitors strip steel thickness in real time during hot/cold rolling, dynamically adjusting mill parameters to enhance product uniformity.

Coil & Plate Specification Verification

Measures steel coil diameters and plate flatness to reduce manual errors and optimize inventory management.

II. Critical Process Positioning & Guidance

Equipment Positioning & Synchronization

Provides precise positioning data for mills, shearing machines, ladle cars, etc., enabling automated actions (e.g., shearing, material handling).

Ensures coordinated operations across production stages via synchronized signal outputs (e.g., RS-485, EtherCAT).

Nivel de oțel topit & Mold Control

Monitors molten steel level in continuous casting molds to prevent overflow or flow interruption.

Tracks steel melt height in converters/blast furnaces with high-temperature-resistant designs to optimize smelting efficiency.

III. High-Temperature Adaptability & Safety Assurance

Reliability in Extreme Conditions

IP67-rated housing and forced-air purge technology resist extreme heat (≥1800°F), dust, and optical interference.

High-temperature-resistant housing ensures stable operation near casting lines and reheating furnaces.

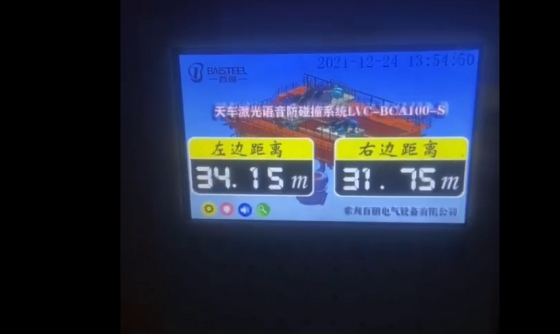

Safety Monitoring & Accident Prevention

Monitors safety distances between equipment and high-temperature materials, triggering alarms to protect personnel/assets.

Detects anomalies like furnace door status or furnace deformation to support maintenance decisions.

IV. Efficiency Optimization & Smart Upgrades

Automated Process Enhancement

Guides AGVs and stacker cranes to optimize warehouse logistics.

Improves reheating furnace temperature distribution via data feedback to reduce energy consumption.

Predictive Maintenance Support

Monitors parameters such as roll wear and equipment displacement to minimize unplanned downtime.

V. Specialized Applications

Slag layer thickness measurement: Integrates AI analytics to refine smelting processes.

High-temperature plate tracking: Real-time feedback on plate positioning in hot rolling mills to ensure production continuity.

Rezumat:

Laser rangefinders enable end-to-end precision control in steelmaking—from raw material processing to final product inspection—while withstanding harsh environments (high temperatures, dust, etc.). Their integration enhances production efficiency, safety, and智能化 (smart manufacturing) capabilities.

Baisteels

Baisteels