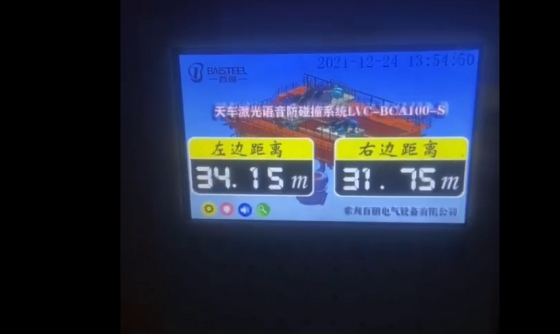

Reflective Laser Detector for Target Presence Detection in Steel Rolling Production Lines

Eu. Product Overview

The Reflective Laser Detector (Link) is a laser-based industrial detection device designed for harsh environments. Utilizing a retro-reflective principle, it emits a laser beam and analyzes the reflected signal to determine target presence. It is ideal for position detection in challenging conditions like steel rolling production lines.

II. Working Principle

In steel rolling lines, the detector operates as follows:

Laser Emission: A 650 nm red laser emitter generates a collimated laser beam.

Beam Transmission: The beam travels through air to illuminate the target (e.g., steel billets, plates) or a preset reflector.

Signal Reflection: The target or reflector reflects the beam back to the detector.

Signal Reception: A high-sensitivity photoelectric receiver captures the reflected beam.

Signal Processing: Internal circuitry converts the optical signal into an electrical output, determining target presence based on signal intensity.

III. Application Scenarios

In steel rolling production lines, the detector is used for:

Material Detection:

Verifies whether billets or plates reach designated positions to trigger subsequent processes (e.g., shearing, rolling).

Safety Protection:

Monitors hazardous zones (e.g., mill entry) for foreign object intrusions, triggering alarms or emergency shutdowns to prevent accidents.

Quality Control:

Combines with sensor data to enable real-time monitoring and adjustments of rolling processes, ensuring product quality.

IV. Key Advantages

The detector offers the following benefits in steel rolling lines:

High Precision & Long Range:

Laser collimation enables long-distance, high-accuracy detection over wide areas.

Robust Anti-Interference:

Advanced signal processing and anti-interference design resist strong light, dust, and vibrations.

Harsh Environment Resilience:

Waterproof, dustproof, and high-temperature resistant housing ensures reliability in extreme conditions.

Ease of Installation & Maintenance:

Flexible mounting for detectors/reflectors; simplified maintenance reduces operational costs.

V. Conclusion

The Reflective Laser Detector delivers precise, reliable target detection in steel rolling lines through its long-range capability, anti-interference performance, and rugged design. By enhancing automation, safety, and quality control, it empowers steel manufacturers to achieve efficient, sustainable production.

Baisteels

Baisteels