From the outlet of the heating furnace to the coiler, hot metal detectors, infrared scanners, and laser measurement sensors are widely used for in place detection, edge positioning, and measurement of hot plate strips. They can work with high precision and reliability in harsh environments such as high ambient temperatures, strong thermal radiation, пар, water, and smoke in the hot rolling area.

Rough rolling area

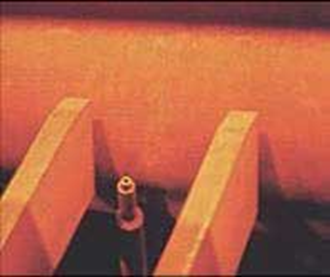

Scanning thermal metal detector tracks hot workpieces.

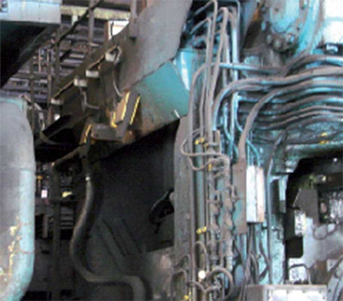

Target detection before flying shear

When environmental conditions, water, and steam make it difficult to detect above the roller conveyor, strip steel workpieces can be detected from below the roller conveyor.

Centering control

Use an infrared loop scanner for strip alignment control.

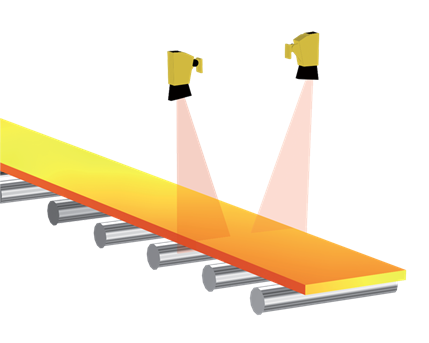

Precision rolling and coiling area

Use high-power reflective gratings or high-sensitivity scanning thermal metal detectors to detect the head and tail of the strip steel at the entrance of the coiler.

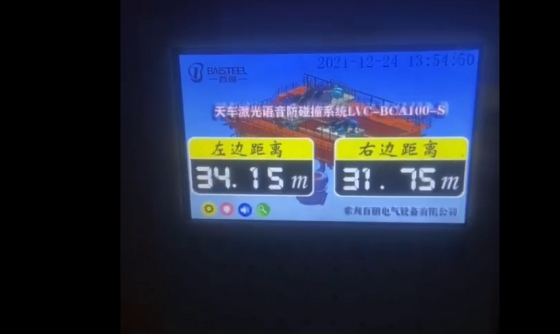

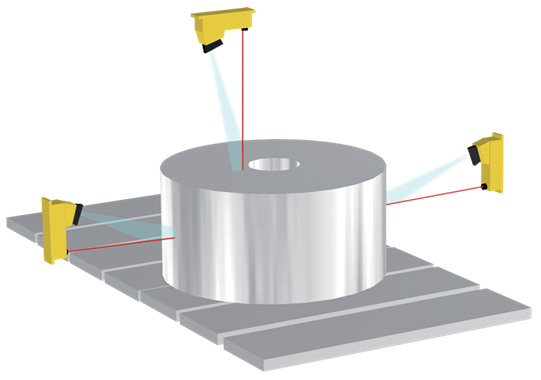

Steel coil transportation

Use laser sensors to measure the diameter of steel coils and control their placement.

Байстилс

Байстилс