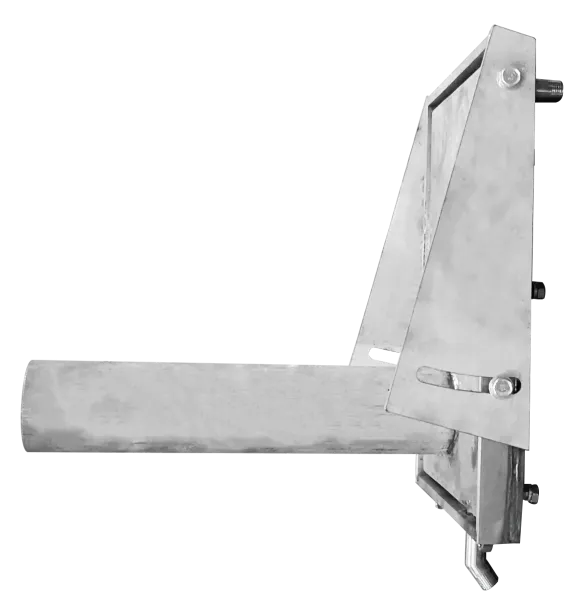

BMH-FC Heating furnace imaging system

I. System brief description

According to the thickness of the furnace wall of different specifications, the equipment can be equipped with three basic endoscopic insertion methods of long, medium and short, under the necessary observation Angle, to avoid the excessive exposure of the front end of the probe cover, extend the service life of the equipment, and ensure safe and stable operation.2. The equipment adopts sapphire high temperature resistant and extended zoom pinhole lens, which avoids the safety risks brought by the passive front of the early endoscopic product camera, and the pinhole is only 1.0m, which greatly reduces the size of the furnace hole and reduces the energy consumption.

High temperature industrial TV monitoring system is an important part of industrial kiln automation. With the rapid development of industrial manufacturing technology in China, the high efficiency, energy saving and safe operation of industrial kiln are particularly important. The overall improvement and continuous progress of industrial automation control technology, through the high temperature industrial TV to industrial kiln monitoring has been widely used. It significantly improves the production efficiency of industrial enterprises and the safety service life of equipment.

The company has long been committed to the development, research and application of high-temperature industrial TV. Successfully developed a series of high temperature industrial TV monitoring equipment, with the eyes of science and technology instead of relying on "human eyes fire" backward technology, makes the operator in the control room can understand the kiln internal work, greatly improve the work efficiency, reduce the labor intensity, effectively improve the level of equipment process control. At present, there are a series of products, such as external peep type, furnace wall automatic protection type, endoscopic wall automatic protection type and blast furnace top sealing type, suitable for a variety of harsh environment and different furnace equipment and technology.

High temperature industrial TV monitoring equipment is a special closed circuit TV equipment used in high temperature environment. It can be widely used in metallurgy, electric power, building materials, light industry, chemical machinery, automatic casting machinery and other industries of heating furnace, steam boiler, salt furnace, glass furnace and other overall thermal processing equipment and automation equipment has been a lot of applications. The series of equipment can directly to the camera inside the furnace furnace body for long-term observation, monitoring the workpiece, material and the operation of the flame, shape, which ensure the production safety, improve product quality, and improve the working environment, reduce labor intensity, also easy to realize centralized scheduling and automatic control of production process.

The system adopts PLC control technology to automatically control the reach and exit of the camera and the lens part. When the power supply of the system, compressed air supply and the temperature in the probe cover exceeds the range, the mechanism can automatically play an automatic protection role for the equipment.

The system adopts pinhole imaging and double spiral air screen technology, which effectively solves the influence of high intensity thermal radiation, dust and corrosion substances in the kiln on the camera lens, greatly improves the reliability of the system, reduces the maintenance requirements of the system, and basically achieves the equipment maintenance free.

Technical feature:

① Feng shui double cooling technology, double spiral wind curtain design

② Unique midcircle isolation technology

③ Dual protection technology, more intelligent, more reliable

④ The PLC control (under pressure / over temperature) automatically exits the system

⑤ Remote temperature alarm system (selected according to the requirements)

⑥ High temperature resistant all stainless steel material, mold manufacturing, unique structure conception and design

⑦ Manual rotation can freely occur to the optimal monitoring angle

Horizontal: 62°~14°; vertical: 48°~10°; diagonal: 100°~17°

⑧ Perfect quality assurance system, training service, spare parts service, follow-up visit, service