BG-BPS800 Scanning Loop Detector

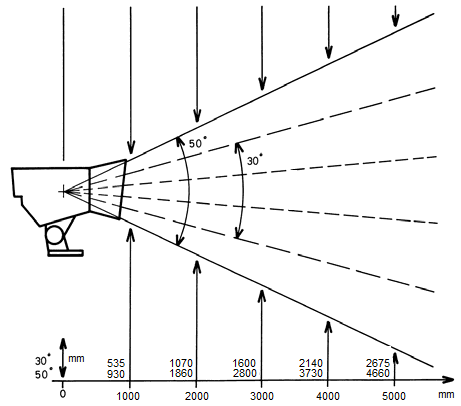

An infrared scanning loop detector based on high-precision measurement detects infrared radiation sources located in a vertical field of view area (very narrow horizontal field of view) of 30 ° or 50 °, and outputs an analog quantity (4-20mA current and 0-10V voltage) proportional to the angle position of the heat source in its vertical field of view. It can be used for loop control and measurement in the metallurgical industry steel rolling process.

This detector is a scanning loop

1.0Overview

An infrared scanning loop detector based on high-precision measurement detects infrared radiation sources located in a vertical field of view area (very narrow horizontal field of view) of 30 ° or 50 °, and outputs an analog quantity (4-20mA current and 0-10V voltage) proportional to the angle position of the heat source in its vertical field of view. It can be used for loop control and measurement in the metallurgical industry steel rolling process.

This detector is a scanning loop detector that is insensitive to the distance of the heat source target and can be installed very far from the measured object. This detector can detect objects with a minimum temperature of 250 ℃.

This detector uses an OLED display screen, and various parameters of the detector’s operation are fully displayed on the display screen, allowing users to have a clear understanding of the operating status at a glance.

Mainly applicable to:

✸Loop adjustment of bar, wire, and hot strip rolling mills;

✸Strip width control;

✸Central positioning of strip and other products

✸The position of the shear head and tail is used for optimizing the action of the profile rolling mill;

✸Edge position control of continuous casting machine and strip

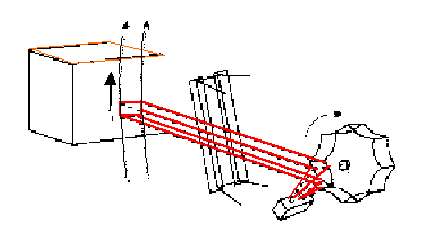

1.0.1 Scanning principle

The optical area of this detector is scanned by a rotating drum with a polyhedral mirror. If a hot metal passes through the field of view of the detector and the detected infrared radiation is reflected onto the photocell, the internal processing circuit converts the optical signal into an electrical signal. By comparing it with the threshold level, a switching value is output. At the same time, the internal processing circuit calculates the position of the infrared radiation source in the entire scanning area and outputs a set of analog quantities (4-20mA current signal and 0-10V voltage signal) corresponding to the percentage of the scanning area, The process is shown in the following figure:

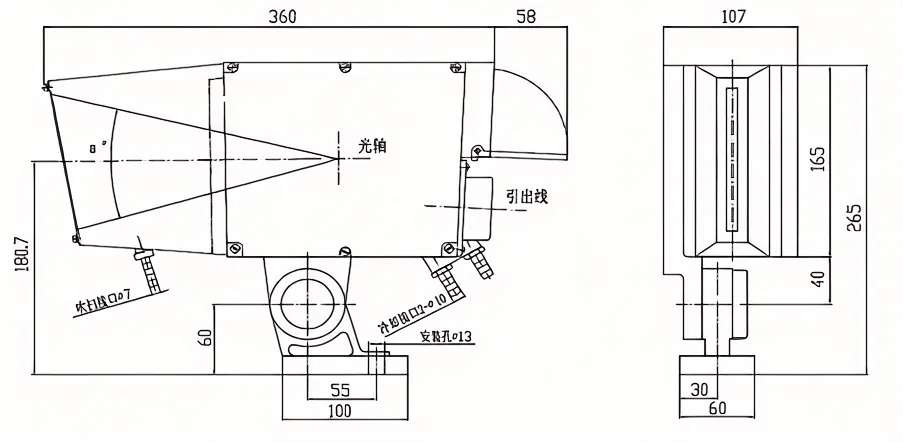

Technical parameters

| Shell form | Cast aluminum casing with cooling | |

| Working power supply | 2:AC220V(±10%); 4:DC24V(DC18V~DC30V); | |

| Power waste | No load ≤ 10W | |

| Vertical scanning angle of view | 30°; 50°;Settable models of 30 ° and 50 ° can be set and selected on site. | |

| Response time | 2ms ; | |

| Special output response time | Increase the relay by about 7ms; MOS optocoupler increases by about 1ms | |

| Analog current output | 4-20mA (maximum load 500 Ω) output mode is determined by the analog output mode | |

| Analog voltage output | The output mode of 0-10V (maximum 10mA) is determined by the analog output mode | |

| Minimum detection temperature | 350 ℃ (normal sensitivity); 250 ℃ (high sensitivity) | |

| Display screen | 1.54 “high-definition OLED screen | |

| Signal energy intensity | 15 level LED light column. | |

| Signal energy intensity output | 0-10V analog voltage output, corresponding to the corresponding signal strength | |

| Action threshold | 15 LED light columns, set different signal action thresholds. It can be adjusted by the panel potentiometer, rotating counterclockwise, with an adjustable range of 2-14 from low to high, corresponding to the action threshold of signal strength. It can also be adjusted by setting the external action threshold pin with an external 10K potentiometer to 0V or an external control voltage of 0-10V-3mA (external action threshold control priority). 0V (potentiometer 0 Ω) corresponds to 2nd gear, and 10V (potentiometer 10K) corresponds to 14th gear. | |

| Signal sensitivity | N: Normal sensitivity; H: High sensitivity; The minimum detection temperature for ordinary sensitivity is 350 ℃. The minimum detection temperature for high sensitivity is 250 ℃. | |

| OUTPUT | Relay(Z) | Maximum contact capacity:AC 250V 10A, DC 30V 10A |

| LEVEL(C) | High push pull level; Maximum load current 100mA; | |

| MOS OptoCoupler(G) | Maximum input working voltage ≤ 400V AC/DC, maximum load current 60mA | |

| Signal energy alarm | Normal: High push pull level; Alarm: Low push pull level, maximum load 100mA | |

| Fault Alarm | Normal: High push pull level; Alarm: Low push pull level, maximum load 100mA | |

| Self Test | Button self check or external passive switch control self check | |

| Laser assisted aiming | 520nm green line laser, 5mW | |

| Insulation resistance | DC500V,≥20MΩ | |

| Circuit protection | DC input polarity protection; Level output short circuit and overload protection; | |

| operation temperature | -25 ℃~+70 ℃; -25 ℃~+120 ℃ with water cooling | |

| cooling water | Pressure 0.1-0.2MPa, flow rate 1-5L/min | |

| Purge air | Pressure 0.05-0.1MPa, flow rate 4-16L/min | |

| protection grade | IP66 | |

| weight | 6.8kg | |